Sample pictures

Performance and use

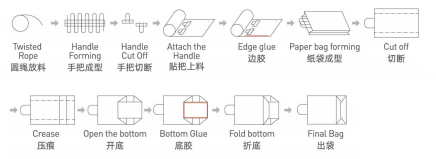

Automatic square bottom paper bag machine, used to produce hand-held paper bags. This machine is especially suitable for mass production of shopping clothes in food and clothing industries. In this machine, the winding rope and the paper roll are made into a hand-held by a hand-held machine, and the hand-held is sent to the paster unit through a conveying system, and then the primary color or printed roll paper is pre-broken at the paper rope position, glued at the paster position, and automatically pasted with the hand-held, and then the paper with the hand-held is coated with edge glue by the host computer. Tube forming, cutting, indentation, bottom gluing, bag bottom forming and conveying out of the bag, and the whole process is completed synchronously at one time. This machine adopts high-speed motion controller (CPU) imported from Germany, which controls the servo operation through high-speed bus to ensure stable motion and smooth motion curve. It is the preferred automatic portable square-bottom paper bag equipment for printing and packaging manufacturers.

Main feature

1.Using French SCHNEIDER touch screen man-machine interface, the operation function is clear and easy to control

2.Using German original LENZE motion controller (PC) to ensure high-speed operation stability through integration with optical fiber

3.Using German original LENZE servo motor with German original SICK photoelectric eye correction, accurate tracking printing bag size

4.The loading and unloading of raw materials adopts hydraulic white lifting structure, and the unwinding adopts automatic constant tension control.

5.raw material correction using Italian SELECTRA, to reduce paper roll alignment adjustment time.

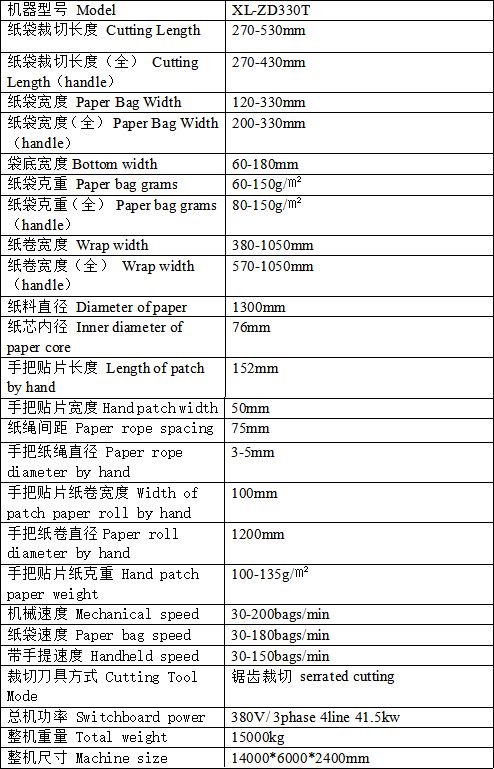

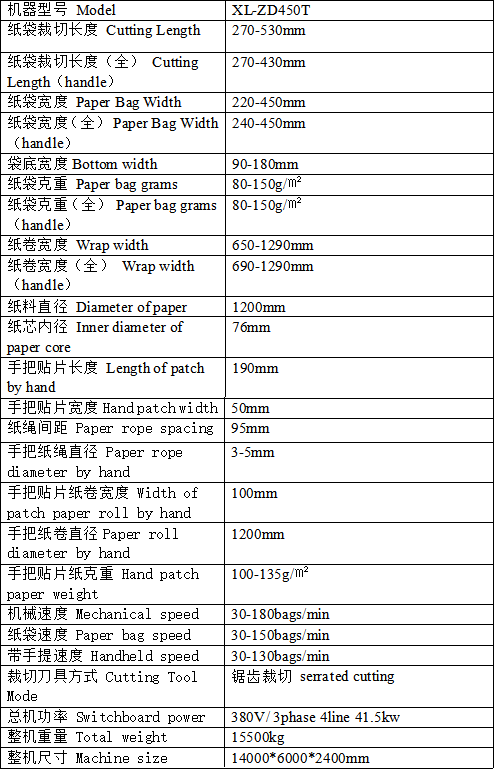

Technical parameters

Flow chart

Configure